|

|

|

|

|

|

|

||||

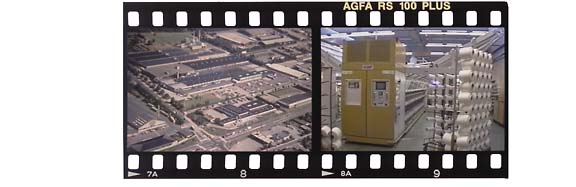

| Textile Production Plant | ||

| Neckelmann is situated in the middle of Jutland in Denmark. The factory buildings and offices covers 40,000m2 and employs a staff of 800. Neckelmann produces textured polyester and polyamide yarns. Yarn breakage is monitored on all bobbins. Production efficiency is also recorded. All data collection is performed by means of P-NET. The factory utilises P-NET compatible equipment for the control and supervision of the large number of machines and systems. The yarns are used to make clothing, upholstery fabrics, original seat covers for cars, and for other technical applications. Different texturising methods are used, such as air-texturising and friction texturising. The textured yarn is heat treated in autoclaves. |

|

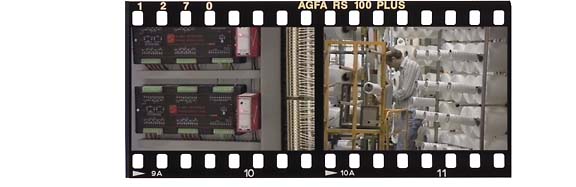

| Each autoclave has its own controller, which operates on its own local P-NET, and all the autoclaves are interconnected within a larger P-NET. A waste heat recovery system is installed in the basement. This system is also controlled via P-NET. A number of PC's collect data from the P-NETs throughout the entire factory. These data are send to an IBM administrative system via an IBM Token-Ring, which can then be processed and displayed on any PC on the network. The factory has its own department for designing, installing and programming the automatic systems. The first P-NET was installed in 1988 and every year, the plant has been extended. |

|

|||||

| Scope of P-NET installation: 4000 Digital Input/Output 200 Analog Input (Pt100, 4-20mA) 30 Controllers with 68000 CPU 4000 meters of P-NET cable |

|

|

|

|

||||

|

|

International P-NET User Organization

DK-8600 SilkeborgDenmark |

Send us an e-mail |